Heavy Lift

At the destination, the cargo is either installed off-shore using floating crane or loaded-in to quayside by SPMT or crane. Subsequently, installation at the foundation is carried out by jack-down or shore crane. Heavy lift plays a pivotal role in installation, be it off-shore, in-shore or on-shore.

Selection of Floating Crane

With an in-depth understanding of available floating crane resources in the region, ROYDEN & JAYSTON offers expert guidance to clients in selecting the most suitable crane for their specific heavy lift requirements. Our approach involves a meticulous evaluation process that takes into account various factors to ensure optimal lift operations:

1. Comprehensive Assessment: We begin by comprehensively assessing the client’s heavy lift needs, cargo specifications, and the operational environment. This includes considering factors like cargo weight, dimensions, lift height, and the conditions at the installation site.

2. Crane Capability Matching: Drawing from our extensive knowledge of available floating cranes and sheerlegs, we match their capabilities to the client’s requirements. This involves scrutinising factors such as lifting capacity, outreach, and stability.

3. Site Analysis: Understanding the installation site’s conditions is crucial. We analyse variables like water depth, seabed conditions, and space availability to ascertain which crane can operate effectively in the given environment.

4. Cost-Effectiveness: We assess the economic viability of different crane options, factoring in aspects like rental costs, mobilisation expenses, and potential downtime. Our goal is to help clients achieve their objectives without unnecessary financial burdens.

5. Safety Considerations: Safety is paramount in heavy lift operations. We consider the safety features and stability enhancements offered by different cranes, ensuring that the chosen crane can safely handle the specific lift operation.

6. Experience and Expertise: With our rich experience in the field, we leverage our insights to offer practical recommendations. Our team has encountered a range of heavy lift scenarios, allowing us to anticipate challenges and identify the most suitable solutions.

7. Tailored Solutions: Every heavy lift scenario is unique. Our guidance is tailored to the client’s specific needs, ensuring that the selected crane aligns perfectly with the project’s requirements.

Rigging Design & Analysis

Rigging gears which encompasses all gears (slings, shackles, spreader, lifting frame) in between the hook and the cargo should be adequately designed to cater for the environment and the crane used. At ROYDEN & JAYSTON, our expertise extends to conducting thorough engineering studies and calculations that adhere to recognised industry standards such as DNV-ST-N001. Our approach takes into account crucial factors including:

- Dynamic amplication factor (DAF)

- Yaw factor

- Skew load factor

- Tilt

- Rigging utilisation factor

We also design spreader beams that are verified and endorsed by Classification Society (e.g. DNV). This comprehensive evaluation ensures that rigging gears are not only designed safely but are also optimised for efficiency and compatibility with both the crane equipment and the operational context.

Lifting Plan & Analysis

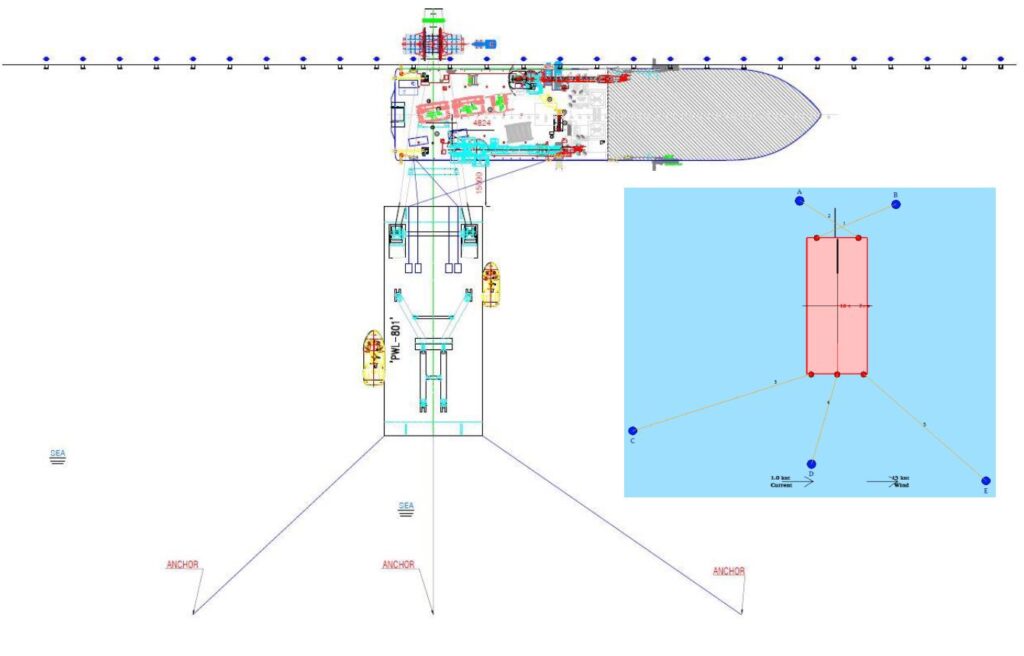

A comprehensive lifting plan and analysis is necessary to ensure a safe execution of heavy lifting operations, minimising risks, optimising resources, and achieving successful outcomes. It provides a visual representation of how the lift will be performed from pick-up to installation, the mooring pattern and the crane’s details.

At ROYDEN & JAYSTON, our expertise covers the following calculations and analyses:

- Derivation of dynamic hook loads

- Crane’s capacity check

- Site water depth and sheerleg underkeel clearance check

- Mooring pattern and anchor points

- Step-by-step lifting procedure

Mooring Analysis

Mooring analysis plays a vital role in ensuring the safety of marine lifting operations. At ROYDEN & JAYSTON, we comprehensively assess various factors to ensure a successful operation:

1. Site Conditions: We carefully evaluate the site’s conditions, including water depth, seabed composition, tidal variations, wind, current, and wave data.

2. Mooring Equipment: Our analysis takes into account the type and strength of mooring equipment being used, such as anchors, chains, ropes, bollards and connecting hardware.

3. Mooring Pattern: We design the mooring layout to evenly distribute the forces and stresses exerted during the lifting operation. Proper positioning of mooring points and angles minimizes the risk of overloading.

4. Dynamic Forces: Mooring lines experience dynamic forces due to changing environmental conditions like wind, waves, and current. Our analysis incorporates these dynamic factors to ensure the mooring system’s adequacy under various environment directions.

Cargo Structural Integrity Check for Lifting

Based on the chosen lifting and rigging configuration, it’s crucial to verify the structural integrity of the cargo for lifting operations. This verification ensures that the cargo’s structure remains safe and stable during the lifting process. Key aspects that require scrutiny include:

1. Cargo Structural Integrity: The overall structural integrity of the cargo needs to be confirmed. This involves assessing the materials, connections, welds, and overall construction of the cargo to ensure they can withstand the stresses imposed by lifting.

2. Lift Points: The points at which the cargo will be attached to the lifting equipment, known as lift points, must be meticulously checked. These points should be strong enough to handle the load without deformation or failure.

3. Load Factors: Load factors, which account for uncertainties and dynamic effects, should be applied to the cargo’s weight and other forces. These factors provide a safety margin to prevent overloading.

4. Finite Element Analysis: Finite Element Analysis (FEA) is used where necessary to simulate the stresses and deformations that the cargo will experience during lifting. This analysis helps identify potential weak points.

5. Compliance with Standards: All calculations, analyses, and designs should adhere to industry standards and guidelines to ensure that the cargo’s structural integrity aligns with recognized safety benchmarks.

Heavy Lift for On-shore Installation

ROYDEN & JAYSTON’s expertise in heavy lift consultancy goes beyond the marine industry. With our experience and familiarity with land cranes (mobile crane, crawler crane, ringer crane) and specialised lifting (gantry lift with strand jacks, hydraulic gantry, push-up system), we can propose solutions that suit your on-shore installation needs.

Whether it’s the construction of a Petrochemical Plant or a Power Plant, our proficiency in heavy lift operations equips us to deliver solutions that prioritise safety, cost-effectiveness and on-time delivery to your project.