Transportation Analysis

Following the successful loadout, the cargo is transported to its intended destination. Depending on the geometry and size of the cargo, detailed transportation analysis is necessary to ensure a safe and optimised operation. Transportation analysis constitutes the comprehensive design and engineering efforts that underpin the success of a transportation operation.

Tug Selection & Towing Gears Sizing

Barges are commonly used for transporting cargo for short distances, inland waterways and are especially useful for shallow water navigation where ships struggle to operate. They are also very useful for transporting oversized and heavy cargo that might be difficult to transport over roads due to weight restrictions or size limitations.

Barges are usually non-propelled and require a tug to perform the towage. Tugs typically constitute a big cost for the transportation. Optimising the selection of tugs by avoiding an unnecessarily oversized tug could result in huge cost savings for our clients. At ROYDEN & JAYSTON, we are familiar with the requirements of the MWS and could size up an adequate and optimised tug for the intended transport route.

We provide calculations and studies that encompasses:

- Bollard pull

- Maximum towing speed

- Towing gears capacity check / selection

- Towing arrangement

- Towing manual

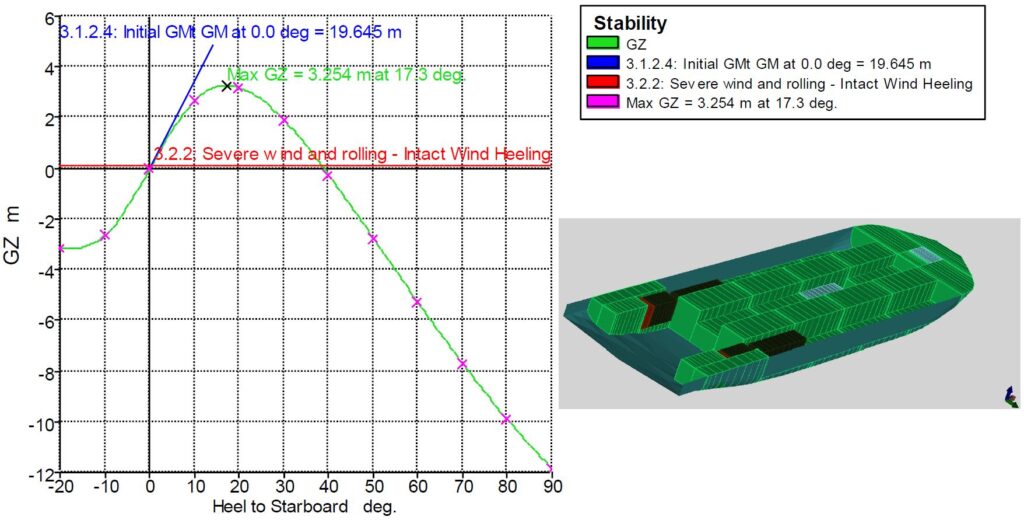

Floating Stability

The floating stability of a vessel is critically important to ensure that the vessel remains upright during the transportation and the cargo is safe throughout the voyage.

At ROYDEN & JAYSTON, we create a detailed 3D model of the vessel and conduct comprehensive stability calculations using established software. Subsequently, we assess these calculations against the relevant Marine Warranty Surveyor’s guidelines for transportation and Class regulations.

We conduct stability assessments for:

- Intact stability

- Wind overturning

- Damage stability

- Draft and trim

Motion Analysis

The dynamic interplay of wind, current and wave action significantly impacts a vessel’s movements in six degrees of motion: three translational (heave, sway, surge) and three rotational (roll, pitch, and yaw). The vessel’s motions influence the potential forces that the cargo might encounter during the voyage.

Design motions can be derived by means of motion response analysis using computer program, model tank testing or calculation using default motion criteria from MWS or classification society rules. Motion response analysis takes into account the most adverse sea state that the cargo could encounter along its route based on the MetOcean data.

Whether it entails intricate evaluations using advanced computer programs or calculations grounded in well-established guidelines with default motion criteria from MWS or classification rules, ROYDEN & JAYSTON is equipped to provide analyses that meticulously cater to your specific requirements.

Seafastening Analysis

To secure the cargo to deck from the motions of the vessel, it is necessary to adequately seafasten the cargo. The computed transverse, longitudinal force and tipping moment (if any) due to the motions of the vessel should be sufficiently secured by the seafastening.

Depending on the size, geometry and weight of the cargo, various seafastening designs can be provided includes but not limited to the following:

- Lashing belts, chains or wires

- Shear stoppers, T-stoppers and dog-plates or clips

- Stanchions

- Pipe bracing designs

For projects involving multiple shipments with similar types of cargo, ROYDEN & JAYSTON could customise reusable seafastening designs specific to the project’s requirements. This approach not only delivers substantial cost savings but facilitate swift assembly and disassembly, reducing the need for extensive modifications between shipments.

Grillage Design

Grillage, a structure secured to the vessel’s deck to support the cargo and to distribute concentrated loads of cargo to the strong points of the vessel should be used where applicable for a safe cargo transportation. Besides loads distribution, grillage also serves the purpose as an elevated structure higher than the minimum trailer height for set-down after trailer loadout or any projection below the cargo support line.

ROYDEN & JAYSTON stands ready to create an efficient solution for your project, offering two distinct avenues:

1. Tailored Single-Use Design: Customised grillage designs optimised for individual cargo transportation; these designs are tailored to meet the specific requirements of a particular cargo.

2. Innovative Reusable Design: Reusable grillage designs that are enhanced to adapt to varying cargo sizes across multiple shipments. This approach optimises operations and contributes to substantial cost savings by eradicating the need for frequent redesigns with cargo variations.

Longitudinal Strength Check

The hull is considered as a girder in a simple beam (Euler-Bernoulli) theory, which is subject to global loads. The load effect of the net weight of vessel’s weight (acting downwards) and buoyancy (acting upwards) results in shear force and bending moment on the hull girder. The bending moment and shear force are computed and checked against the allowable limit to ensure a safe transport.

At ROYDEN & JAYSTON, we create a detailed 3D model of the vessel using recognised computer program. This model is used in our analysis of the vessel’s longitudinal strength, wherein we account for all weight components, including lightweight and deadweight (cargo, grillage, ballast, etc), at their respective positions. These calculations are subsequently simulated under a design significant wave height to confirm that the longitudinal strength requirements are complied with.

Our expertise covers these services:

- Vessel’s hogging and sagging

- Deflections of vessel during transportation

- Shear force and bending moment

- Optimised cargo position and ballast conditions

Module Structural Integrity

ROYDEN & JAYSTON’s expertise in ensuring the structural integrity of modules during sea transportation encompasses a wide range of critical factors. Our comprehensive approach includes:

All-encompassing Load Cases: We meticulously assess various load scenarios that the module may encounter during sea transportation. This includes evaluating different loading conditions, forces, and dynamic effects to ensure the module’s robustness under all conceivable circumstances.

Structural Integrity Verification: Our experts verify the integrity of the module’s structural elements to evaluate the module’s ability to withstand the dynamic forces and stresses imposed by sea conditions. This includes assessing the module’s response to wave-induced motions, accelerations, and other external influences. This comprehensive process involves evaluating connections, welds, and critical load-bearing points.

Deck Local Strength Check

Deck local strength, like its name suggests is the strength of a localised structure, like a web girder or a longitudinal for loads experienced locally. The strength should be checked to confirm that the vessel has adequate strength to withstand the localised loads imposed by the cargo during the transportation, including the heave accelerations.

At ROYDEN & JAYSTON, we create a detailed finite element model of the vessel taking into consideration the relevant structural components under the loads. The vessel is then analysed to compute the maximum stress and checked against the allowable stress. Beam models are also code checked to recognised international structural codes and standards, ensuring that the vessel is poised to safely accommodate the localised loads and motions experienced during cargo transportation.