Load-out / Load-in

Loadout is the process of transferring cargo from the quay to a vessel (barge, self-propelled vessel, deck carriers, etc) is often achieved through various methods such as SPMT (Roll-On, Roll-Off), cranes, sheerlegs (Lifted Loadout), or through the use of strand jacks, skid shoes, or winches (Skidded Loadout).

Trailer Strength & Stability

When utilising hydraulic trailers for load relocation, multiple critical factors necessitate meticulous attention. At ROYDEN & JAYSTON, we offer our expertise to provide you the comprehensive engineering, which include:

- Hydraulic grouping and trailer stability calculation

- Trailer’s stability on strength calculation

- Trailer’s spine beam calculation

- Trailer’s acceleration and securing calculation

Route Survey

Through our extensive transport route surveys, we commit to delivering an all-encompassing approach that tackles every aspect of transporting oversized or heavy cargoes. This service extends not only from the fabrication yard to the quayside for loadout but also encompasses the conventional road transportation.

- Obstacles identification and removal plan

- Maneuvering plan to identify obstacles

- Alternative route planning

- Temporary infrastructure, for example ramp or reinforcement structure to facilitate safe passage

- PE’s report to comply with LTA requirements

Ballast Plan & Stability Analysis

For lifted loadout operations where the cargo is stowed at the midship of the vessel, minimal ballasting or no ballasting is usually required due to the balanced weight distribution. However, when it comes to trailer loadout and skidded loadout operations, the process demands a step-by-step ballast sequence to maintain the vessel’s level with the quay within a safe tolerance.

Leveraging our insights into local quays in the region, we prepare ballast plans that factor in the unique attributes of each site and the local tidal variations. Our Ballast Plan integrates tide variations, water depths, and quay height to determine the optimal times for loadout commencement, execution, and completion.

We provide ballast plan and stability analysis for various loadout arrangements as follows:

- Stern-on (mediterranean) loadout

- Transverse loadout

- Vessel to vessel load transfer

- Grounded loadout

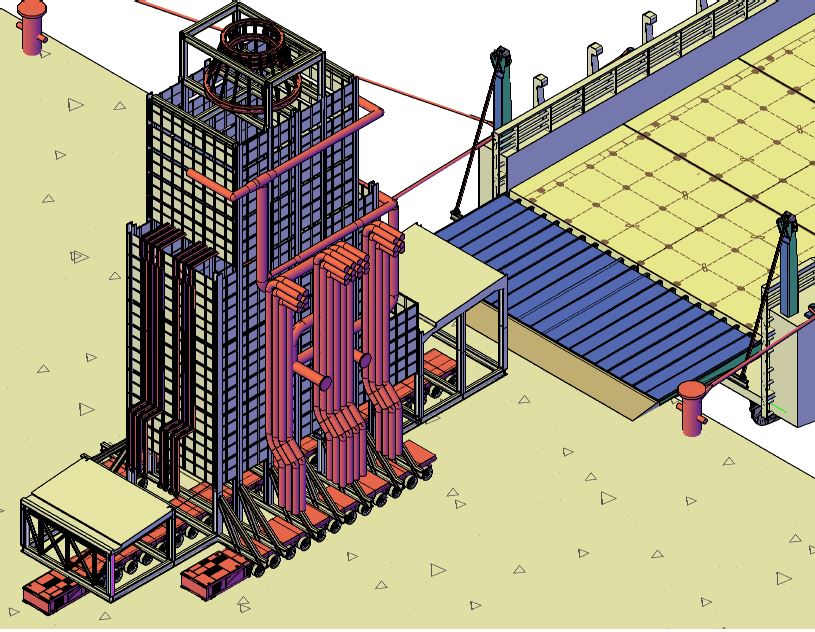

RO-RO Ramp Design

The RO-RO Ramp or link beam/link span is a connecting beam between the quay and the vessel. It is a connection used to transfer the cargo horizontally from quay to vessel, accommodating trailers/SPMTs for roll-on-roll-off (RO-RO) operations or skidshoes for skidded loadouts.

At ROYDEN & JAYSTON, we specialize in designing RO-RO ramps that are tailored to diverse trailer types and capacities. Our innovative designs not only ensure efficient cargo transfer but also offer the advantage of cost savings for our clients. These ramps are engineered to be adaptable and reusable across various trailers and loadout configurations, further enhancing cost-effectiveness and flexibility.

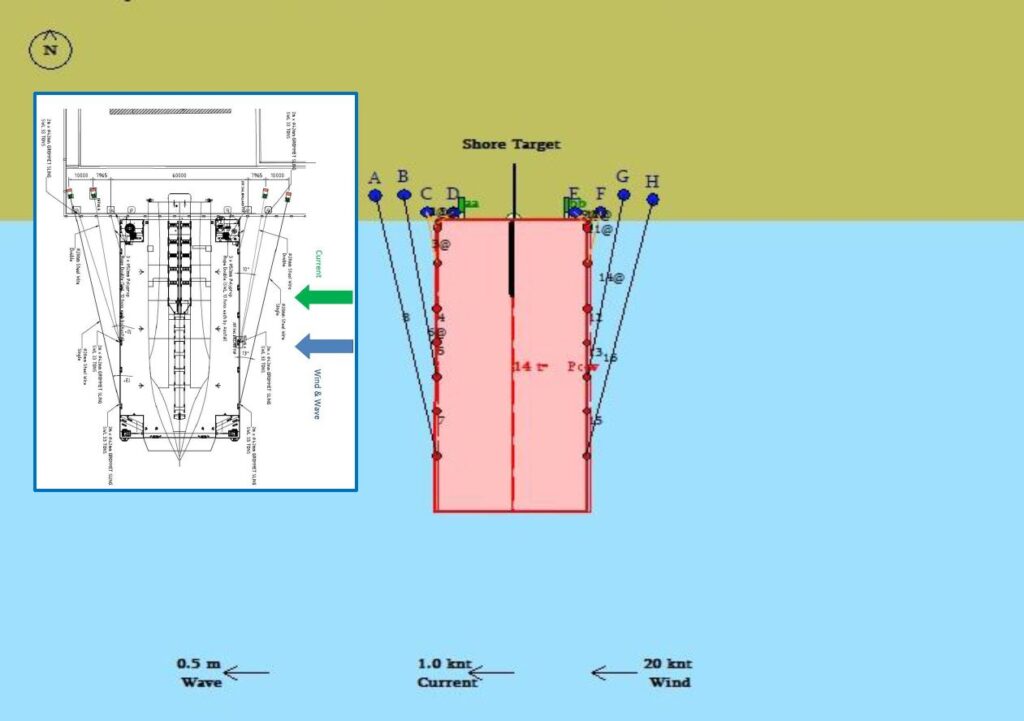

Mooring Analysis

During loadout, keeping the vessel stationary is essential for a safe operation. Be it a stern-on loadout (mediterranean moor), transverse loadout or a vessel-to-vessel transfer, the mooring design has to be adequate to restrain the environmental forces the vessel is exposed to. Beyond addressing the forces induced by wind, waves, and currents, the mooring design must also factor in the tidal range and water depth, including any potential effects of current blockage at the specific location.

Depending on the requirements of the loadout, we can design the mooring arrangement to cater for:

- Intact case

- Redundancy check (single line failure)

Fendering

When a vessel is moored to the quayside, the fenders play a pivotal role by absorbing the energy generated during berthing, as well as effectively countering the mooring forces. This is essential not only during the loadout itself but also in the pre-loadout and post-loadout phases.

At ROYDEN & JAYSTON, our expertise encompasses a thorough understanding of fender dynamics and their role in loadout operations. We check the fenders to cater for both operational demands of berthing and loadout.

Key considerations include:

- Berthing Energy Calculation

- Loadout-Specific Considerations

- Pre-Loadout and Post-Loadout Phases

Longitudinal Strength during Loadout

The transfer of cargo from the quay to the vessel induces a downward force on the vessel, causing the vessel to move downwards, trim and possibly heel (if the load is not equally distributed transversely). To counterbalance this load transfer, appropriate ballasting of the vessel is necessary.

These change in the loads also introduce stress to the vessel’s structure. To ensure that the vessel’s bending moment and shear forces remain within permissible limits, we conduct a comprehensive longitudinal strength analysis for each phase of the ballasting sequence.

Local Strength at Ramp during Loadout

The use of RO-RO Ramp subjects the vessel’s edge to concentrated ‘knife loads’ during loadout. To confirm that the resulting stress remains within the permissible limits of the vessel’s structural integrity, we conduct a detailed finite element analysis.

This analysis is specifically executed at the precise location where the ramp interfaces with the vessel, ensuring an accurate assessment. If deemed necessary, the ramp can be strategically positioned at the vessel’s strong points. Alternatively, exploring a different arrangement of ramps could potentially reduce the localised stress on the vessel’s structure. This approach underscores our commitment to optimising safety and minimising structural strain during loadout operations.